PROFINET

Application Overview

PROFINET operates in challenging industrial environments and is capable of delivering high speed and precise data transmission for equipment control and monitoring required by manufacturing plants. PROFINET I/O (L2 switches) is used for data exchange between I/O controllers (PLC) and I/O devices (field devices). PROFINET switches must be capable of transmitting real-time data from I/O devices to I/O controller while prioritizing the PROFINET packets since they are critical information-carrying packets.

Key Considerations

- PROFINET switch operates in both Ethernet as well as PROFINET networks.

- Fast and secure data transmission to deliver reliable network status information for decentralized analysis.

- High reliability and redundancy, fast boot-up time, status parameters and flxible topologies.

- Compatible with ModBus applications and Ethernet (TCP/IP) communication.

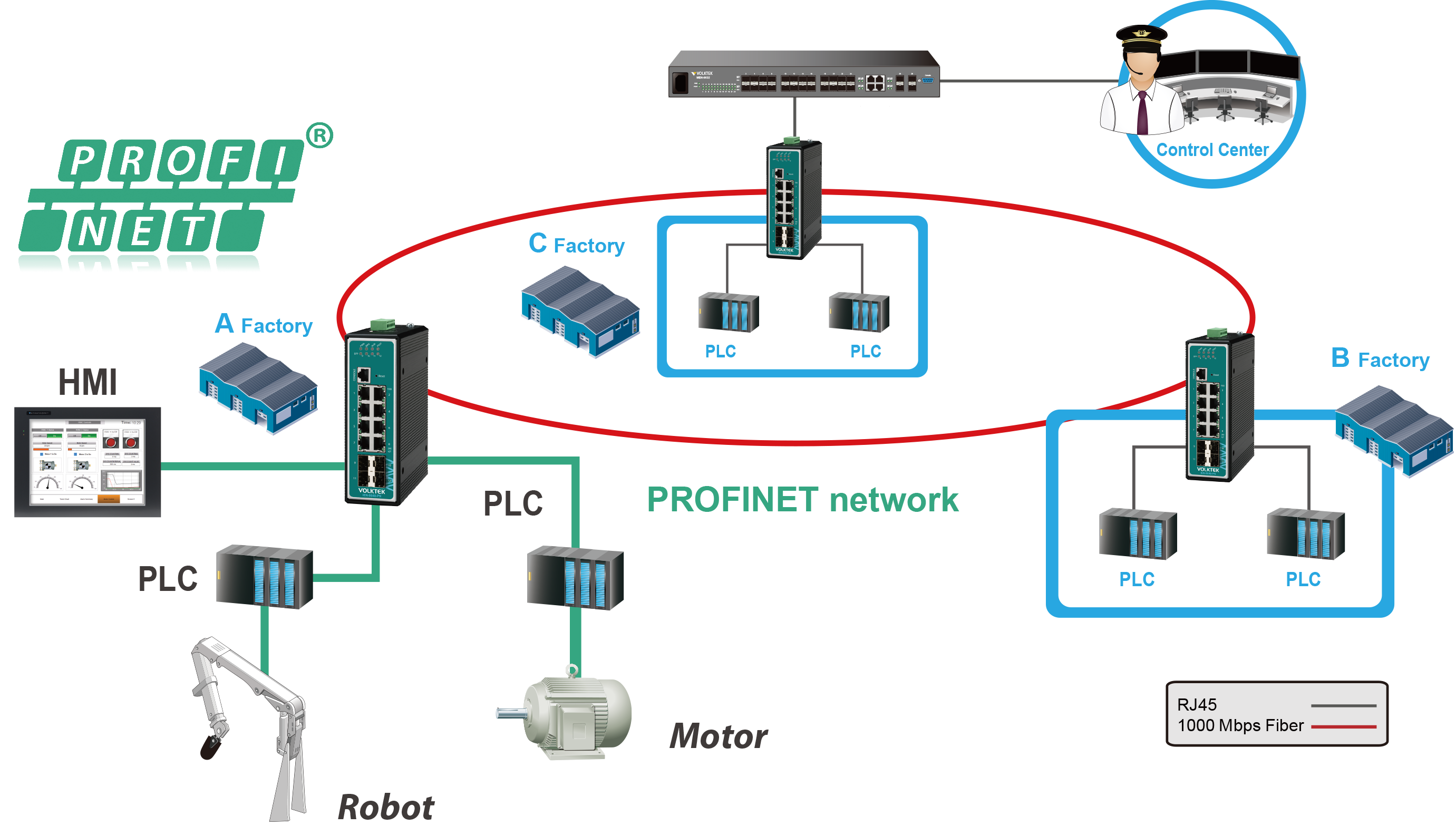

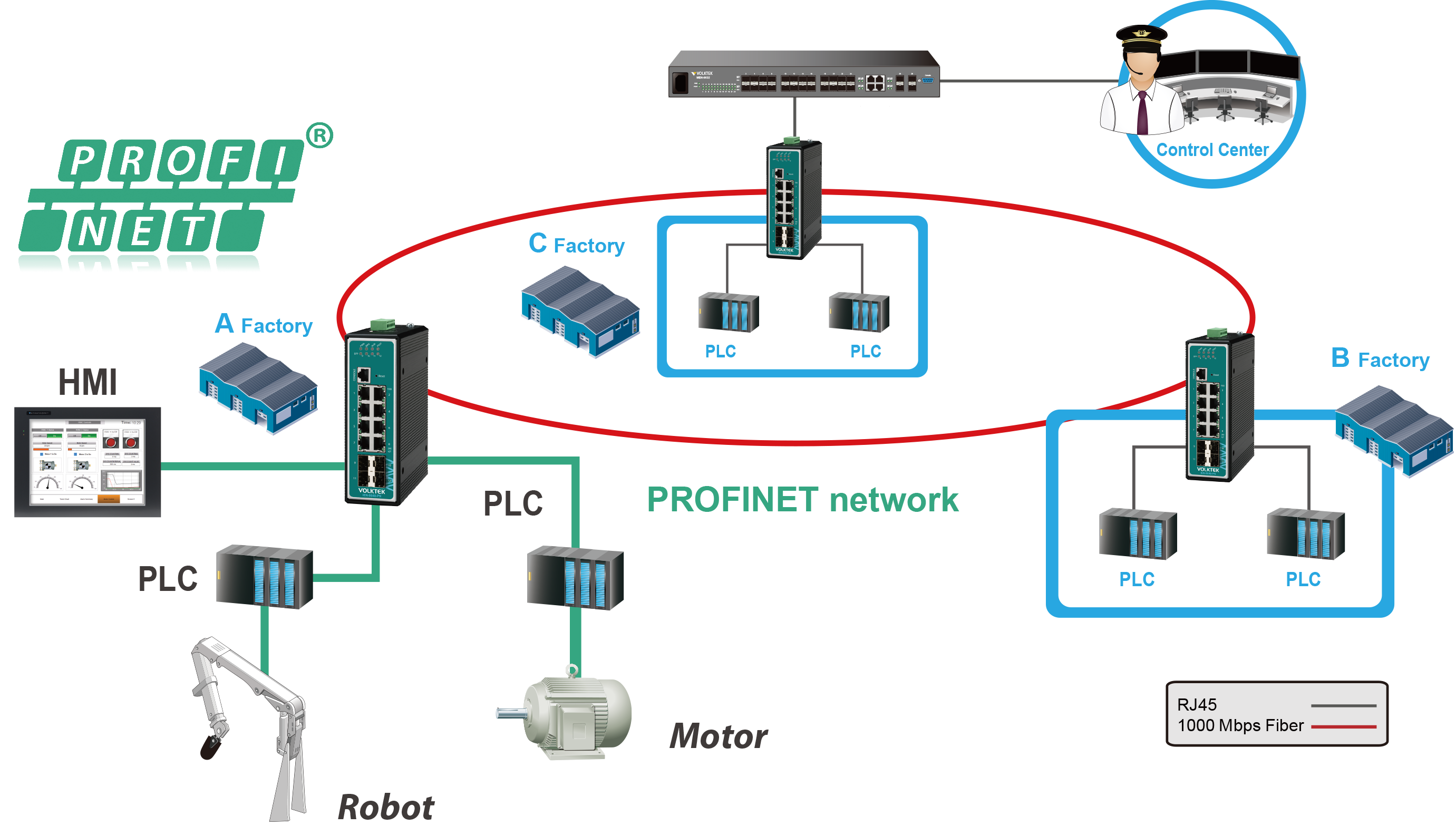

Application Diagram

Recommended Products

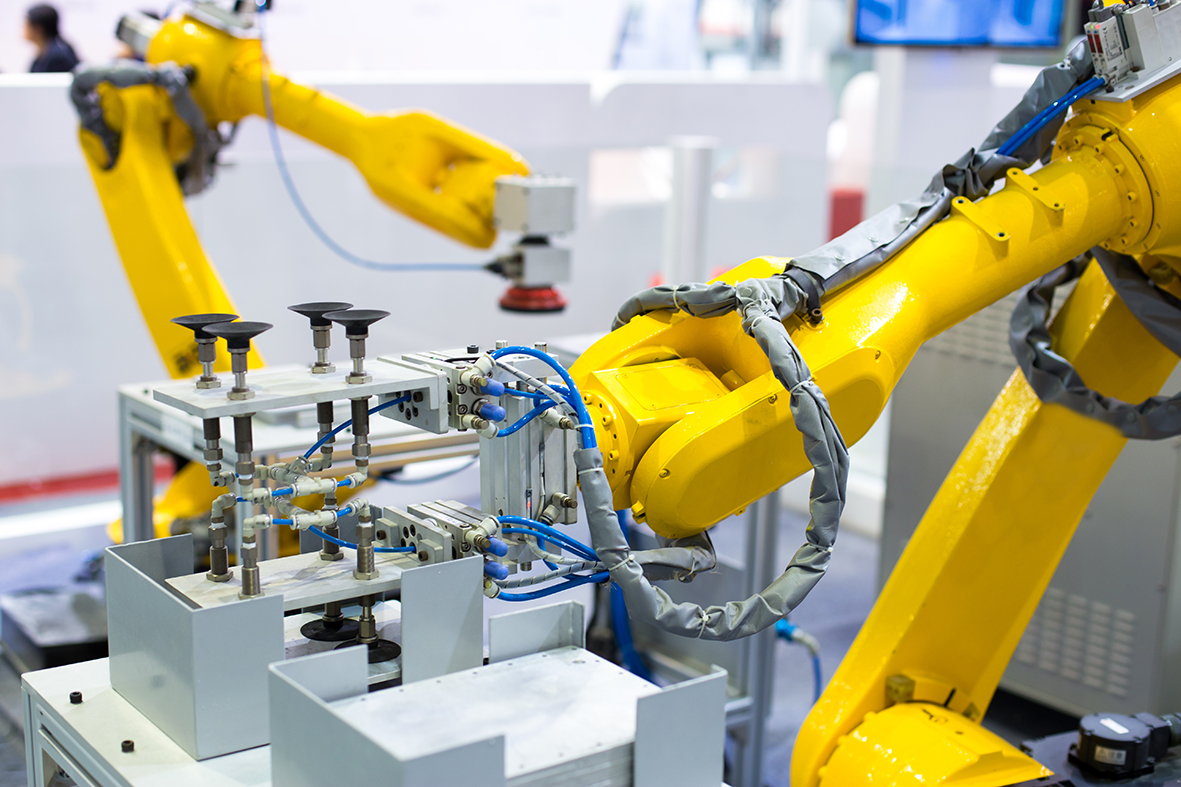

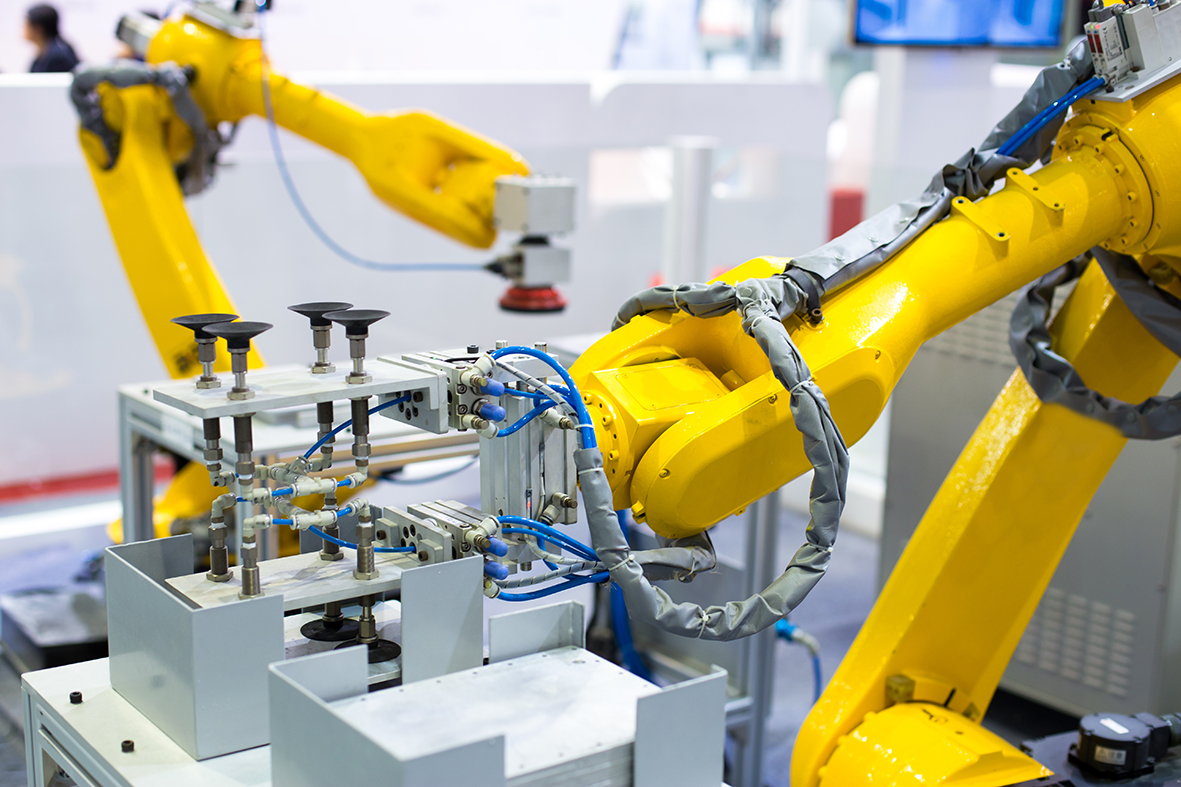

Robotics

Application Overview

To increase productivity, efficiency and accuracy, industries commonly use programmable robots for repeatable operations such as welding, gripping, spinning, and fitting. The data is sent through a PLC (Programmable Logic Controller) to a SCADA system to be analyzed so that robots can be remotely controlled. The Ethernet devices connected to the PLC need to be robust and reliable and able to withstand harsh factory environments.

Key Considerations

- Industrial Ethernet switches that can withstand constant vibration, heavy shocking, high humidity, high ESD (electrostatic discharge), and temperature fluctuations (from -40°C to 75°C).

- Email real-time alarm messages in case of hardware or system malfunction.

- Rugged devices that can be integrated with any large-scale SCADA monitoring system for production and processing automation.

- Redundant ring architecture enhancing network reliability.

Application Diagram

Recommended Products

Factory Automation

Application Overview

PLC's and RTU's are microcomputer which communicate with devices such as machines, sensors and end-devices and route the information to computers with SCADA software. The SCADA software processes, distributes and displays the data, helping operators and other employees analyze the data to mitigate downtime. The systems require redundant link s and operate in a wide, industrial environmental range.

Key Considerations

- Redundant ring topology with millisecond scale network recovery for maximum uptime real-time video and data transmission.

- Industrial grade switches with protection against ESD, and certified with EMI/EMC.

- Rugged devices that can be integrated with any large-scale SCADA monitoring system for production and processing automation.

- Email real-time alarm messages in case of hardware or system malfunction.

Application Diagram

Recommended Products

Factory Security

Application Overview

Factory sytems commonly use 24VDC in harsh environments with PoE+ (up to 30W) for powered devices such as surveillance, WLAN, VoIP phones. Network systems require ruggedized equipment capable of 24/7 monitoring.

Key Considerations

- PoE+ switches with DC/DC boosting technology to provide the required voltage if the input voltage is below the required range.

- Total PoE+ power budget of 240W or 124W when the input voltage is 48VDC or 24VDC respectively.

- PoE+ ports comply with IEEE 802.3at standards, supplying 30W to support powered devices such as WLAN AP, VoIP phones and IP surveillance cameras with up to 100m via CAT 5e cables.

- Industrial grade switches with protection against ESD, EMI/EMC, under and over-voltage conditions.

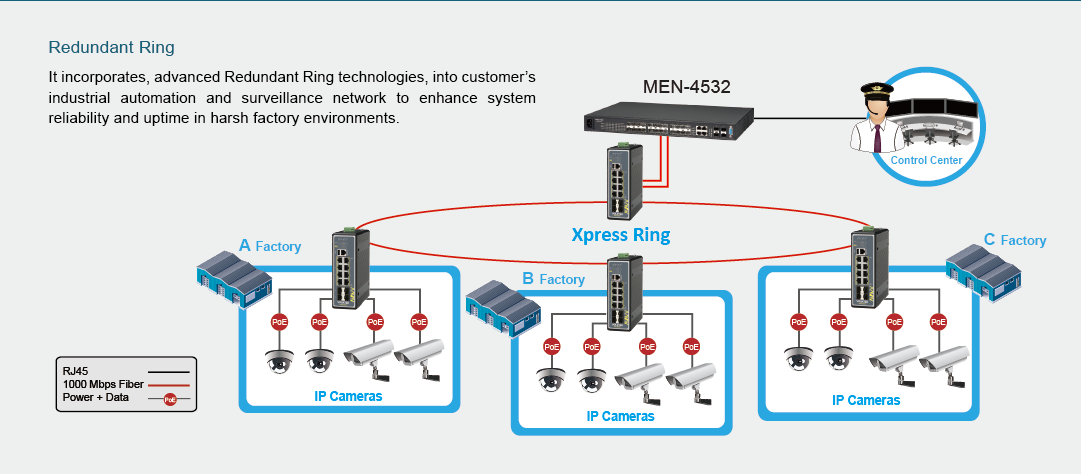

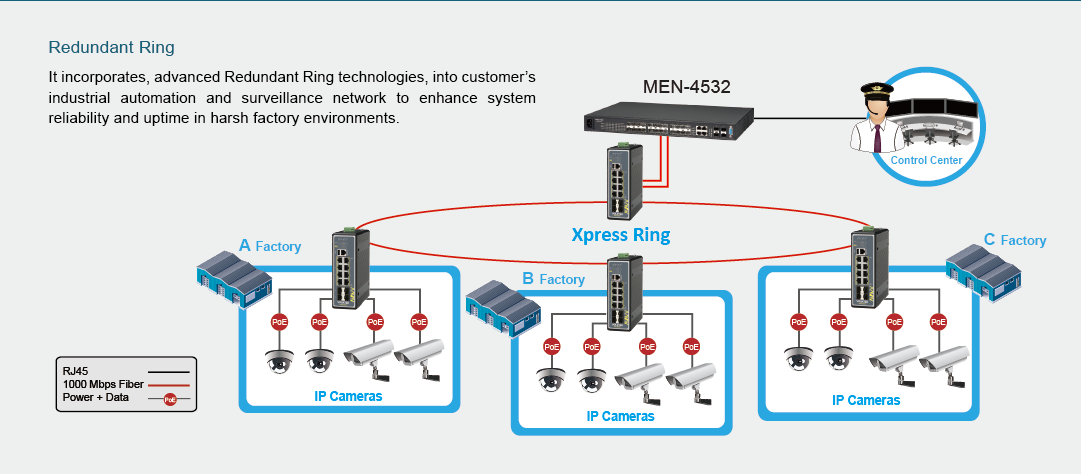

Application Diagram

Recommended Products

Waste Water Management

Application Overview

Waste water management is crucial for maintaining safe regeneration of clean water. The applications require a reliable industrial ethernet network to collect information from PLC, SCADA system, water sensors and water bumps.

Key Considerations

- Redundant ring topology with millisecond scale network recovery for maximum uptime real-time video and data transmission.

- Ruggedized metal housing with IP30 certification for mechanical stress, humidity, dirt, dust, shock and vibration with temperature range of -40°C~75°C.

- Future-proof fiber connectivity for long distance transmission.

- Industrial protocol compatible with SCADA, PLCs, and water sensors.

Application Diagram

Recommended Products

Susbtation Automation

Application Overview

Power utilities commonly utilize Gigabit-speed Ethernet systems in substations for automatic control, protection, remote maintenance and disturbance analysis. These systems are mission critical requiring ruggedized, redundant networks to ensure maximum system reliability.

Key Considerations

- Industrial grade switches for protection against ESD and certified with EMI/EMC protection with overvoltage and overcurrent protection.

- Low maintenance costs (OPEX) with remote management functions.

- Auto-provisioning to update the firmware for the entire network, rather than only a single switch.

- Precise synchronization as per IEEE 1588v2 to simplify integration of all functions.

- Extensive management and filter functions with a variety of redundancy protocols and port security.

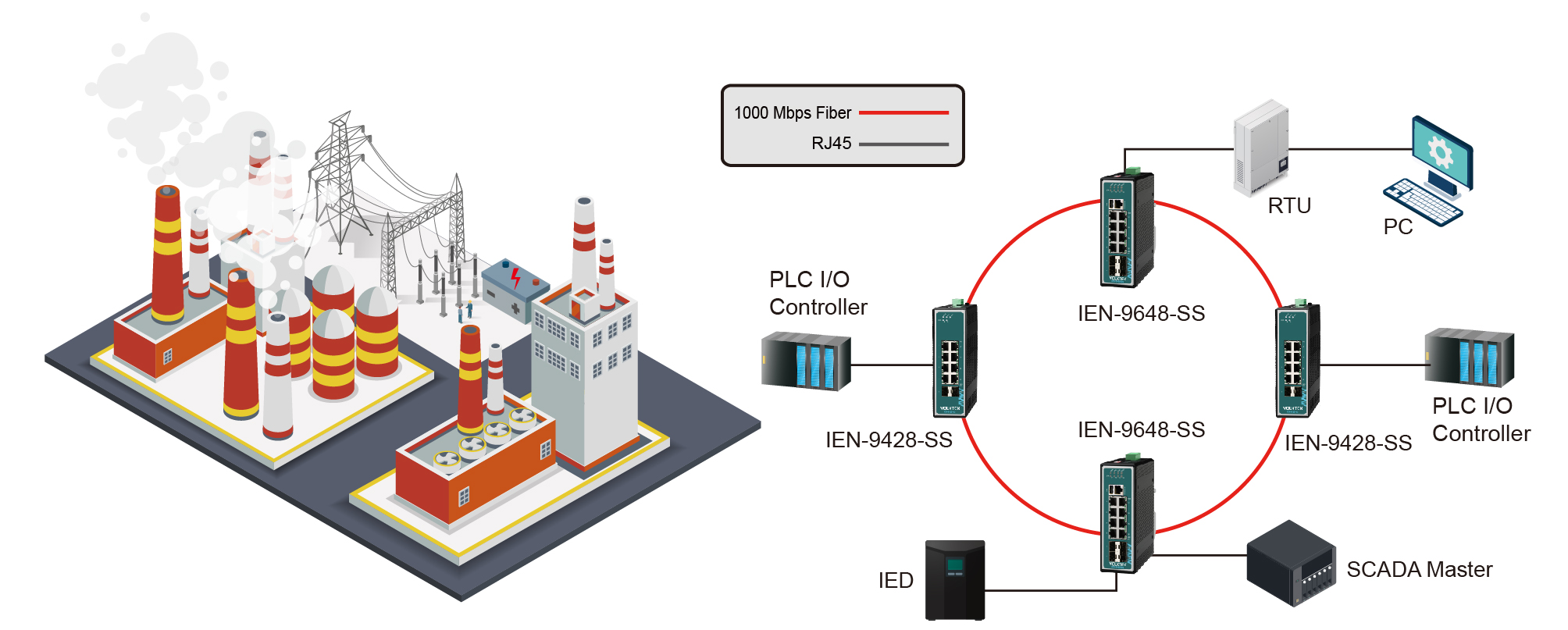

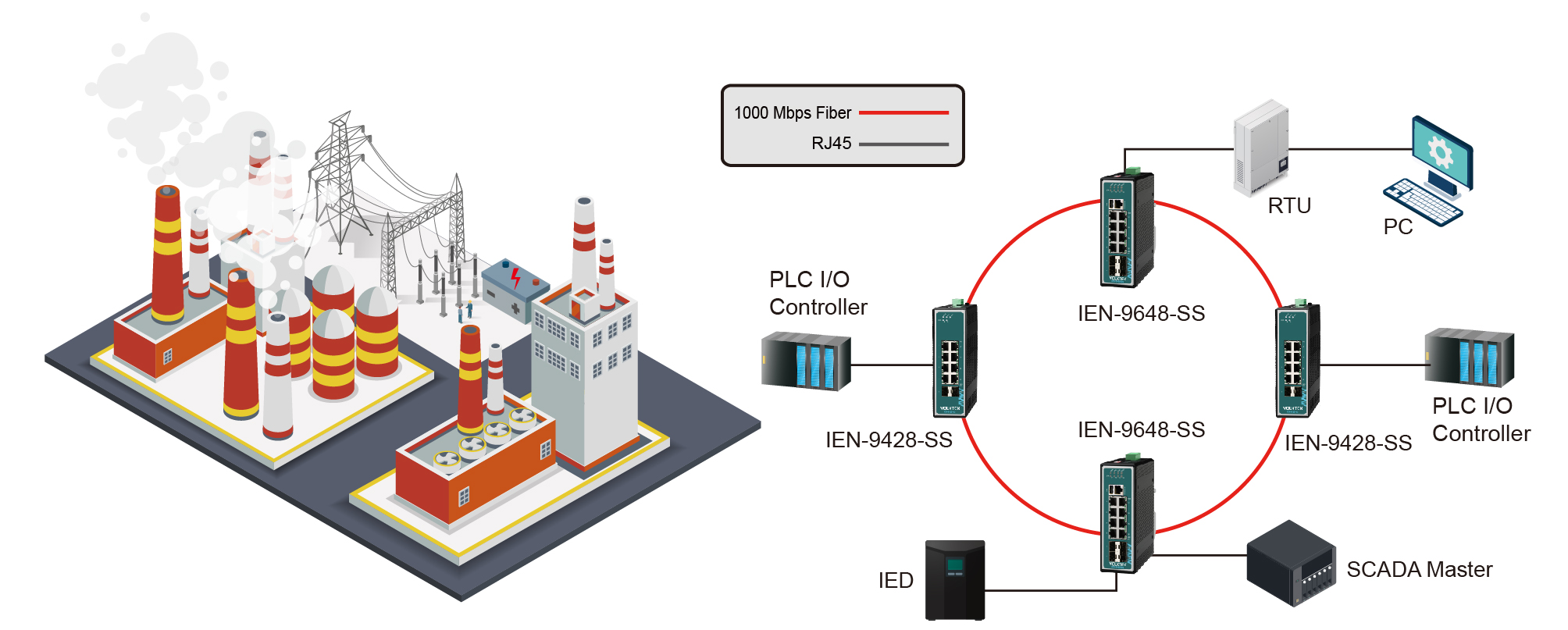

Application Diagram

Recommended Products

.jpg)